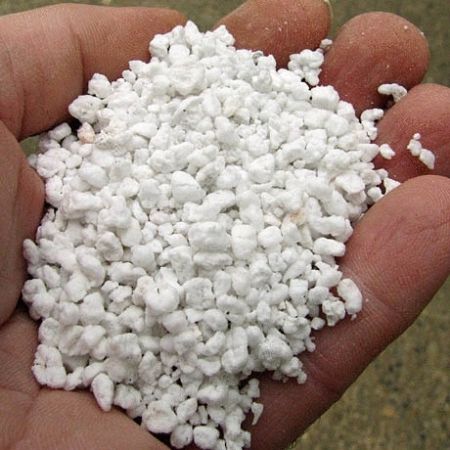

Applications and Uses of Perlite in Insulation

With its Light Weight and Naturally Heat-resistant Composition, Perlite is Valued as a Superior Insulator

Expanded perlite is used a loose fill insulator in double-walled storage tanks and block walls. As a lightweight insulator, perlite is incredibly versatile, meeting a variety of insulating needs—from the super-cooling demands of cryogenics to ambient and low temperature applications up through intense high temperature demands such as foundry cores, molds and even as a crucible topping. Perlite is non—combustible, with fusion point of 1260 degrees C (2300F) and is an ideal loose-fill or spray-on fire-proof insulation for safes, safe rooms, doors, pizza ovens, and chimney linings

There are numerous benefits of using perlite for insulation, including:

Building and Masonry Fill

Energy Savings

Because of its unique closed cell structure, masonry fill insulation can drastically reduce heat transmission through masonry walls. The efficiency of perlite loose fill insulation has led to its almost exclusive use in insulation tanks containing liquified gassed where temperatures of -320°F and below must be maintained. Thermal performance tests show significant energy savings when perlite is used to fill cavities in concrete masonry structures. These tests have determined that perlite masonry fill insulation can be more effective than polystyrene beads, polyurethane foam, polystyrene inserts, vermiculite core fill insulation, and foamed-in-place insulation.

Fills All Voids and Cavities

In addition to its closed cell structure, a key to perlite’s performance is its ability to seek out and completely fill all crevices, voids, and mortar areas in a masonry wall without bridging. This flowability characteristic of perlite masonry insulation assures a completely and efficiently insulated wall. In addition, this flowability feature enables the masonry contractor to install several courses of block before pouring insulation into cavities and/or core holes. Because perlite masonry fill insulation is non-settling and will not compact under its own weight, it is a permanent insulation that will last the life of the structure.

Easy Installation

As perlite masonry fill insulation is field installed following the layering of several courses of block, it does not interfere with masonry contractor nor is it subject to damage in handling. Free-flowing perlite masonry fill insulation is merely poured into cores, ear holes or cavities by means of a simple hopper. No special equipment or skills are required to properly insulate a masonry wall with masonry fill perlite insulation.

Non-Combustible and Fire Ratings

Perlite is a Class A, Class 1 building material with a temperature range for fusion of 2,300 to 2,450 degrees Fahrenheit. Underwriters Laboratories show that a fire rating of a 2-hour rated 8, 10, or 12-inch concrete block wall is improved to 4-hours when cores are filled with masonry fill Tests show that a two-hour rated 8”, 10”, or 12” concrete block wall is improved to four hours when cores are filled with perlite masonry fill insulation. In addition, perlite insulation does not generate fumes when heated. These features of masonry fill insulation make the product particularly suitable for insulating stairwells and elevator shafts.

Inorganic

Perlite masonry fill insulation is permanent and will not rot or otherwise decompose. In addition, it is termite, rodent, and vermin resistant and will not support fungus growth.

Economical

Because perlite masonry fill insulation is a permanent and efficient insulation, it will provide energy saving dividends year-after-year for the life of the structure. Energy savings alone will quickly pay back the cost of the insulation and will decrease building heating and cooling costs for years to come. In addition to being lower-cost than other fillers, perlite is lightweight and pours easily without the need for special equipment or training.

Perlite Insulating Concrete Pool Base for in-ground vinyl pools

Refurbishing an in-ground pool with a new, insulating, perlite-concrete pool bottom.

A perlite insulating concrete pool base can substantially reduce heat loss to the ground

Perlite insulating concrete pool base can substantially reduce heat loss to the ground thus keeping pool water warmer for a longer swimming season.

This will reduce energy costs when pool water is heated. In addition, perlite pool base provides a firm, smooth, foundation that prolongs the life of vinyl liners.

Common Uses for Perlite as an Insulator

- Masonry stones

- Chimney lining

- Underground pipe and ducting concrete

- Concrete pool base for in-ground vinyl pools

- Cryogenic service

- Floor systems

- Roofing

- Metal Decks